Ukuze kuhlangatyezwane nemigaqo ye-GMP, amagumbi acocekileyo asetyenziselwa ukuveliswa kwamayeza kufuneka ahlangabezane neemfuno zomgangatho ofanelekileyo. Ke ngoko, ezi ndawo zemveliso ezingasebenzi kakuhle zifuna ukubekwa esweni okungqongqo ukuqinisekisa ukuba inkqubo yemveliso iyalawuleka. Iindawo ezifuna ukubekwa esweni okubalulekileyo zihlala zifaka iseti yenkqubo yokubeka esweni iinxalenye zothuli, equka: ujongano lolawulo, izixhobo zolawulo, ikhawuntara yeenxalenye, umbhobho womoya, inkqubo ye-vacuum kunye nesoftware, njl.

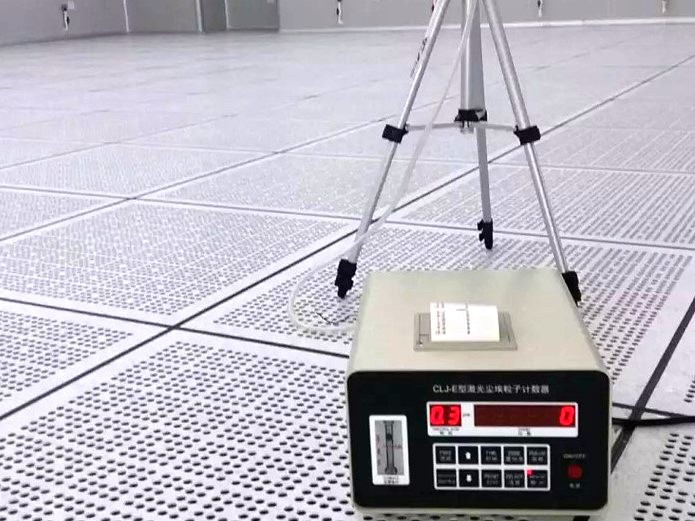

Ikhawuntara yothuli lwelaser yokulinganisa okuqhubekayo ifakiwe kwindawo nganye ebalulekileyo, kwaye indawo nganye ijongwa rhoqo kwaye ithathwa iisampulu ngomyalelo wokuvuselela ikhompyutha yendawo yokusebenza, kwaye idatha ejongiweyo idluliselwa kwikhompyutha yendawo yokusebenza, kwaye ikhompyutha inokubonisa kwaye ikhuphe ingxelo emva kokufumana idatha kumqhubi. Ukukhethwa kwendawo kunye nobungakanani bokubeka esweni okunamandla kwi-intanethi kwamasuntswana othuli kufuneka kusekelwe kuphando lovavanyo lomngcipheko, olufuna ukugubungela zonke iindawo ezibalulekileyo.

Ukumiselwa kwendawo yokuvavanya isampuli yekhawuntara yothuli lwelaser kubhekisa kule migaqo mithandathu ilandelayo:

1. Inkcazo ye-ISO14644-1: Kwigumbi elicoca ukuhamba komoya ngendlela enye, izibuko lokukhupha iisampulu kufuneka lijonge kwicala lokuhamba komoya; kwigumbi elicoca ukuhamba komoya ngendlela enye, izibuko lokukhupha iisampulu kufuneka lijonge phezulu, kwaye isantya sokukhupha iisampulu kwizibuko lokukhupha iisampulu kufuneka sisondele kangangoko kwisantya sokuhamba komoya ngaphakathi;

2. Umgaqo we-GMP: intloko yesampulu kufuneka ifakwe kufutshane nokuphakama kokusebenza kunye nendawo apho imveliso ityhileke khona;

3. Indawo yokuthathwa kwesampulu ayizukuchaphazela ukusebenza okuqhelekileyo kwezixhobo zemveliso, kwaye ayizukuchaphazela ukusebenza okuqhelekileyo kwabasebenzi kwinkqubo yemveliso, ukuze kuthintelwe ukuchaphazela itshaneli yezothutho;

4. Indawo yokuthatha isampuli ayizukubangela iimpazamo ezinkulu zokubala ngenxa yamasuntswana okanye amathontsi aveliswa yimveliso ngokwayo, nto leyo ebangela ukuba idatha yokulinganisa idlule ixabiso elimiselweyo, kwaye ayizukubangela umonakalo kwi-particle sensor;

5. Indawo yokuthathwa kwesampulu ikhethwa ngaphezulu kwendawo ethe tye yenqaku eliphambili, kwaye umgama ukusuka kwindawo eliphambili akufuneki udlule kwi-30cm. Ukuba kukho ukuchitheka kolwelo okanye ukugcwala kwindawo ekhethekileyo, okubangela ukuba iziphumo zedatha yokulinganisa zidlule umgangatho wengingqi wale nqanaba phantsi kweemeko zokuveliswa ezilinganisiweyo, umgama kwicala elithe nkqo unokunqunyelwa. Phumla ngokufanelekileyo, kodwa akufuneki udlule kwi-50cm;

6. Zama ukuphepha ukubeka indawo yokuthatha isampuli ngqo ngaphezulu kwendlela yokudlula kwisikhongozeli, ukuze kungabangela umoya owaneleyo ngaphezulu kwesikhongozeli kunye nokuxinana.

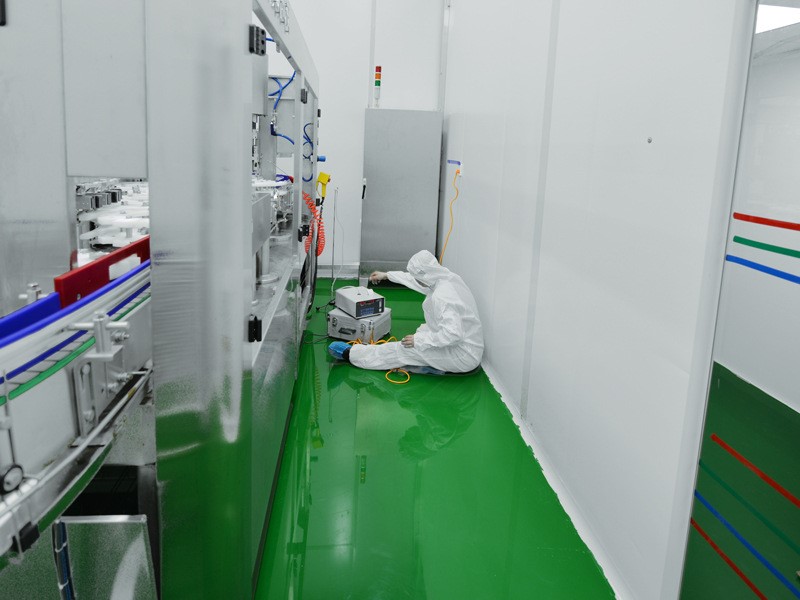

Emva kokuba onke amanqaku afanelekileyo efunyenwe, phantsi kweemeko zendalo yemveliso eqikelelweyo, sebenzisa ikhawuntara yamasuntswana othuli lwelaser enesantya sokuhamba kwesampulu se-100L ngomzuzu ukusampula inqaku ngalinye lomviwa kwindawo nganye ephambili imizuzu eli-10, kwaye uhlalutye uthuli lwawo onke amanqaku afanelekileyo okuvavanya idatha.

Iziphumo zokuthatha iisampulu zamanqaku amaninzi kwindawo enye ziyathelekiswa kwaye zihlalutywe ukuze kufunyanwe indawo yokubeka iliso enomngcipheko ophezulu, ukuze kuqinisekiswe ukuba le ndawo yindawo efanelekileyo yokufaka intloko yokubeka iisampulu zothuli.

Ixesha lokuthumela: Agasti-09-2023